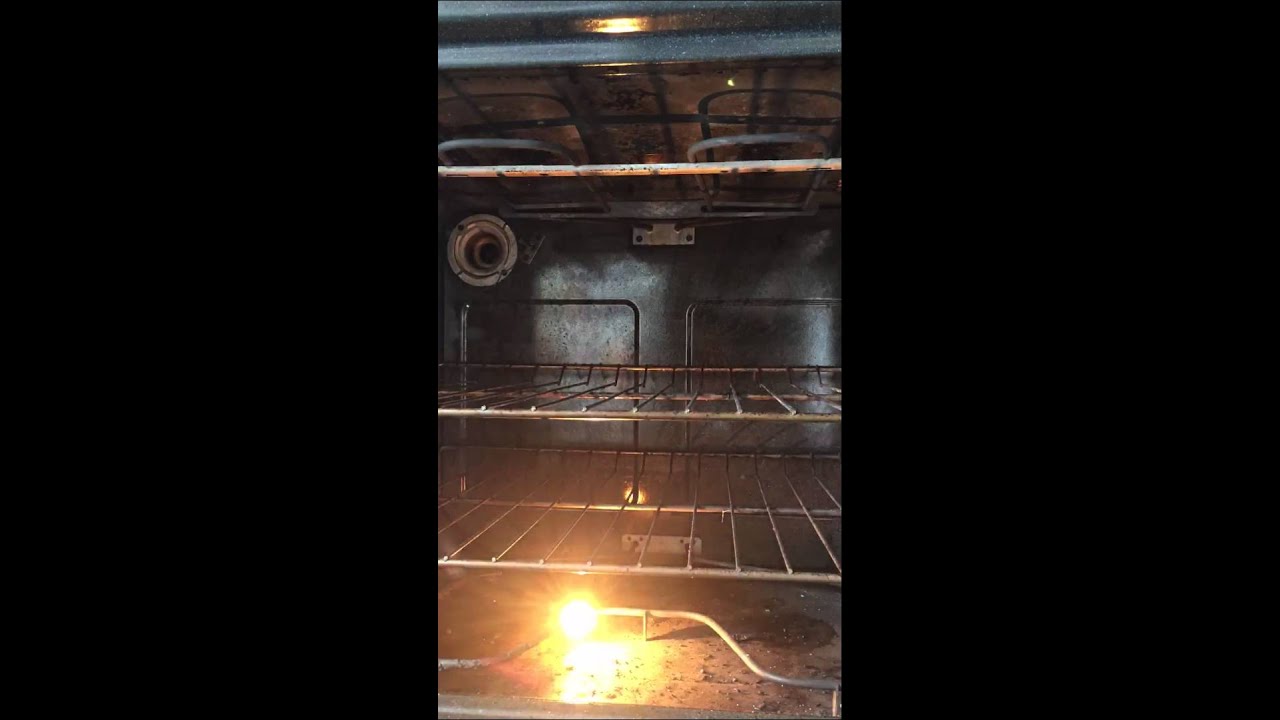

The heating element design layout is reasonable, the temperature inside the furnace is even, air convection is favorable to the evaporation and discharge of water after heating of wet workpiece, which improves the service life of heating element.ĥ The furnace door is equipped with a safety device, when the door is opened, the door automatically closes to ensure the safety of the operator.ĦThe furnace is made of new high temperature resistant and light weight material, which has the characteristics of high efficiency, energy saving and environmental protection. This oven has also a wax draining system and the relevant collection tray to. Proven intermittent power failure function to control the heating speed, to ensure the quality of plaster type sintering and improve the output rate of castings.Ĥ. Hydraulic Logo Stamping& Blanking MachineġWax burnout oven is specially designed for secondary combustion, it recollects the incomplete part of the dewaxing process and re-burns it to fully burn and minimize the wax smell in the environment.ĢFull automatic temperature control with over-temperature protection and break-even protection to prevent the stove from burning out of control and causing fire hazards.ģ:.

to assist the customer in the installation and commissioning of t…

#Burn out oven manual#

1-15kg Manual Tilting Gold smelting furnace.It’s hard to imagine a world without steel – … Steel fueled the industrial revolution and remains the backbone of modern industrialized economies. Precious Metal Melting Furnaces – Humans have been making iron and steel for centuries.

0 kommentar(er)

0 kommentar(er)